As a B2B firm within a furniture hardware industry, any company must be able to minimize shipping cost to remain profitable. Managing packaging plans is a very important factor in the enhancement of the supply chain, minimization of costs and safe transport of products. Smart packaging contains entirely cost-saving and positive returns for a furniture hardware manufacturer or a distributor purchasing great amounts of cabinet hinges, for example.

Importance of Packaging in Logistics

Besides shielding merchandise during transportation, packaging has a role in the transportation system. From the point of view of furniture hardware manufacturers, poor packaging leads to customers’ complaints and broken items that have to be returned or replaced which bring additional costs.

Manufacturers and suppliers of bulk cabinet hinges, drawer slides or door handles are always in the lookout for efficient packaging solutions that are however strong, compact and environmentally friendly. The right approach optimizes shipping costs and protects the company’s products from damage whilst upholding sustainability policies.

Optimize Package Dimensions

Aber eines der schnellsten und wirkungsvollsten Mittel zur Reduzierung der Versandkosten ist die Verbesserung der Abmessungen des Verpackungsmaterials.

Reduce Unused Space

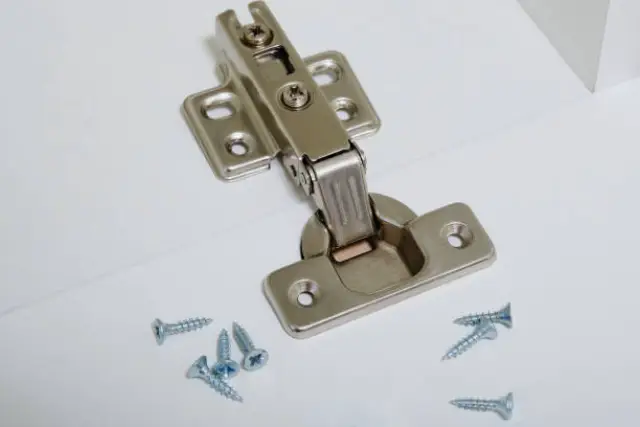

Furniture hardware parts like hinges, handles, knobs, etc., are usually supplied packed in standard sized boxes which easily results in a bulk of void space. By positioning your products to fill its packing dimensions perfectly you decrease the dimensional weight which is used to calculate shipment costs.

For instance, such combined shipments as bulk cabinet hinges can be shipped in packages that are especially designed for such products, thereby avoiding the use of large boxes and therefore cutting on the costs of freight. Manufacturers should also investigate more specific packaging configurations which provide tight packing to shipper standards.

How to Stack and Snow and Pallet Slews

In describing the optimized packaging, they pointed out that it should be well designed for stacking to enhance optimization of the pallet layouts. Manufacturers of furniture hardware should avoid the use of many small differently dimensioned boxes since they are cramped and take up too much space during shipping. It also minimizes the pallet usage in the supply chain, thus minimizing transport cost across the chain.

Use Lightweight and Durable Materials

This remains another of the cost saving strategies highlighted that requires the right choice of packaging material for shipment.

Adoption of Lightweight Packaging

Though durability is important, using very heavy weight materials for packaging can greatly increase the cost of transportation. Replacing materials that are bulky such as cardboard by corrugated cardboard or by plastics that can be recycled will lessen the package weight. For example, manufacturers of large quantities of cabinet hinges should look for lightweight materials that offer security during transportation at a lower cost of the ferrying fees.

Invest in Advanced Protection

Typically, molded pulp or foam inserts that are created for the precise shape of the furniture hardware can ensure the supplementing part is shielded adequately in transportation. Selecting excellent protective packaging lowers the possibilities of achieving a defective product hence less replacement and returns but more customer satisfaction.

Implement Eco-Friendly Solutions

Sustainability cannot be an option anymore; it is a function of the current business environment. The use of green packaging in B2B organizations can be seen to have both short-term and long-term benefits such as cost savings, benefit of the brand image and environmental conservation.

Sustainable Packaging

Recyclable material use for packaging means there are less left over products, which would be beneficial for buyers who want to be environmentally friendly. Other categories of packaging that have added advantages of cost cutting are reusable packaging, for instance hardware like crates and modular packaging.

Furniture hardware manufacturers can also suggest adapting colleagues’ packaging or providing biodegradable packaging for large orders, including hinges, slides, or locks, which will help to push for themselves as environmentally friendly and socially responsible partners.

Optimize Packaging Design

Energy-efficient designs usually require less material in their construction hence they cost less to produce and are easy on the environment. For instance, furniture hardware components can be packed in flat-pack and literally mean packing flat to occupy less space, have low dimensional weight compared to other shapes hence enabling efficient shipments.

Leverage Automation and Technology

Applying technology advancement to your packaging will not only improve efficiency but also save you a lot of money.

Automated Packaging Systems

All of the packaging systems that were described in this article can be further divided into two categories: automatic and semiautomatic.

Preformed packaging applications might help avoid operator mistakes and variations in the form of packaging, thereby increasing productivity. They are particularly useful to furniture hardware makers receiving bulk orders of plain cabinet hinges or any other product. This can also improve on the conservativeness of the material used, which will also minimize other costs that can be associated with material purchase.

As discussed before, it is essential to track and measure packaging performance regularly by following certain metrics;.

The implementation of an application used to track the packaging performance enables businesses to point out unnecessary usage as well as potential amendments. Through understanding the flow of shipping manufacturers can also be able to change packaging solutions to best meet problem solving and material costs. For instance, manufacturers may observe that some products regularly attract high shipping expenses on account of their weight or measure; it is possible to redesign approaches to product packaging in such cases.

Collaborate with Logistics Partners

Additional benefits arising from collaborative outsourcing include also bringing down the overall costs of shipping through proper packaging options.

Seek Expert Guidance

Most logistics companies extend advisory services relevant to packaging and freight management to corporations. Companies such as furniture hardware manufacturers who transport standard items such as large bulk of cabinet hinges can discuss with its logistics provider to achieve economical solutions that will ease the implementation of shipping.

Consolidate Shipments

Transshipment means consolidation of many small consignments and they jointly are transported which ultimately contributes to decrease in overall costs. This is made possible by packaging where consolidation of shipments is inevitable in an attempt to reduce freight costs while in the process having to make optimum use of space.

For the furniture hardware industry’s B2B enterprises, cutting delivery expenses using effective packaging techniques can be a boon. So, by improving dimension, using materials that are lightweight, using green methods, technologically aided inventions, and associating logistics with furniture, hardware manufacturers are able to increase productivity and decrease costs without harming product quality.

In both dispatch of large quantities of cabinet hinges or any other furniture hardware parts, emphasis on Packaging will create strong bond, lesser cost and competitive market edge.